We may not see it with our eyes every day, but polyvinyl alcohol is used in so many forms and applications. Essentially, polyvinyl alcohol is a synthetic polymer that is soluble in water. It is white in colour and odourless as well. When polyvinyl alcohol suppliers send it across for use it is done so in the form of beads or mixed with water.

What makes polyvinyl alcohol different from other polymers is the process in which it is created. Polyvinyl alcohol manufacture involves a process called hydrolysis. In this process, polyvinyl acetate is dissolved in alcohol (methanol) and then treated with sodium hydroxide which is an alkaline catalyst. What results from hydrolysis is a polymer that is highly soluble in water but which is insoluble in all organic solvents.

There are two industries that are primarily catered to by polyvinyl alcohol suppliers: the textiles industry and the paper-making industry.

In the textiles industry, polyvinyl alcohol is used to strengthen textile yarns. The process is called sizing of yarn. What sizing does is to reduce the chance of breakage while the yarn is on the weaving machine. This abrasion-resistance will enhance the strength of the yarn and also decrease its hairiness. Sizing in the textile industry is done either by hand or by suing machines.

In the paper industry, polyvinyl alcohol is used to make the paper more resistant to both grease and oil, thus making it more stable for use. It also adds surface gloss and smoothness to the treated paper.

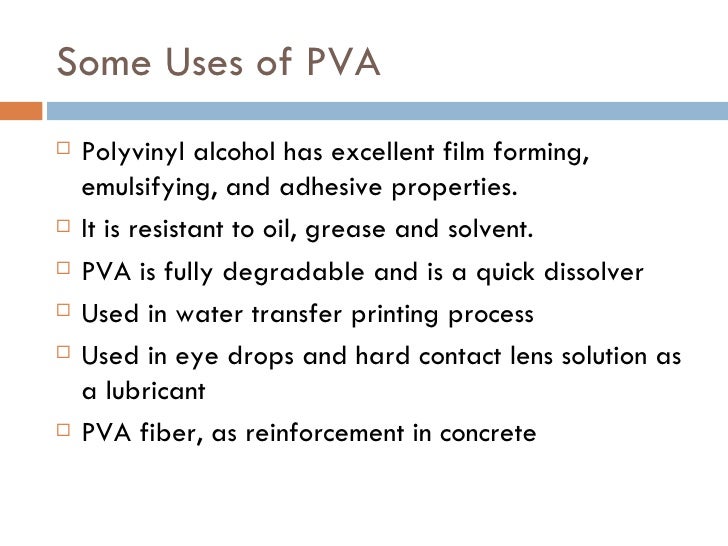

Apart from being used in the paper and textile industries polyvinyl alcohol has other uses as well.

The simple reason why polyvinyl alcohol finds so many uses is that it is non-toxic. Moreover, it is biodegradable, strong and odourless as well.

You must be logged in to post a comment.